Naphthalene refining rate is the ratio of the amount of naphthalene in the naphthalene refining product to the amount of naphthalene in the raw material, expressed as a percentage.

It is one of the indicators to evaluate the naphthalene oil fraction processing and naphthalene refining process and operation level.

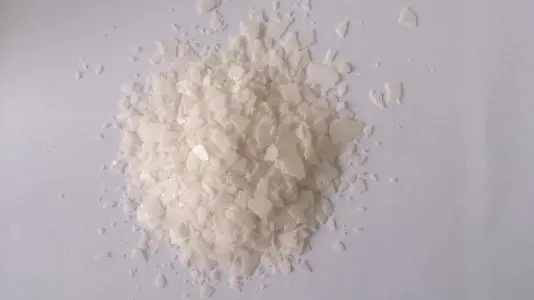

In addition to naphthalene, technical naphthalene also contains a variety of impurities, such as thiophene, phenols, quinolines and unsaturated compounds.

To obtain high quality refined naphthalene, it is necessary to further refine the technical naphthalene.

The traditional method is acid distillation, and gradually developed are solvent method, catalytic hydrogenation and crystallization method.

1.Introduction of naphthalene refining rate

Naphthalene refining rate refers to the ratio of the amount of naphthalene in the naphthalene refining product to the amount of naphthalene in the raw material, expressed as a percentage.

It is one of the indicators to evaluate the naphthalene oil fraction processing and naphthalene refining process and operation level.

Its calculation formula is:

Naphthalene refining rate = [naphthalene refining product output * naphthalene content (%)]/[raw material amount * naphthalene content (%)

2. Naphthalene refining crystallization and separation method

Raw material naphthalene (such as industrial naphthalene, etc.) to naphthalene as a key component,

to the other key component of thiophene, two key components of the boiling point difference of only a few degrees, such a difference to take distillation separation is exceptionally difficult.

The difference between the crystallization point of these two key components is 49℃, the crystallization point of naphthalene is 80.3℃ and that of thiindene is 31.3℃,

so it is easy to separate them by crystallization process. Crystallization refining method, the process is simple, mature technology, low energy consumption.

Crystallization refining process is the use of high crystallization point of the material first crystallization,

while the low crystallization point of the impurities are still in the liquid state of the principle, through multiple crystallization, melting, so that the material to establish a new equilibrium.

Each time the material is crystallized and melted, it is purified once, and the process is repeated several times to finally obtain the required high-purity refined naphthalene product.

The number of repetitions depends on the requirements for the quality of the naphthalene product, the higher the requirements,

the more repetitions will be made, while the naphthalene refining rate will be reduced. Crystallization refining can be generally summarized into three steps.

(1) Crystallization process. Generation of crystals and release of residual liquid.

(2) Sweating process. By heating, the impurities in the crystalline crystals slowly melt and are removed by penetrating the surface of the crystals.

(3) Total melting process. By increasing the temperature of the heat carrier, all the crystals are melted at once

3. Naphthalene refining process

Naphthalene refining rate is the ratio of the amount of naphthalene in the naphthalene refining product to the amount of naphthalene in the raw material, expressed as a percentage.

Is one of the indicators to evaluate the naphthalene oil fraction processing and naphthalene refining process and operation level.

Its calculation formula is:

Naphthalene refining rate = [naphthalene refining product output * naphthalene content (%)]/[raw material amount * naphthalene content (%)。

4. Environmental impact of refined naphthalene

Health hazards

Intrusion route: inhalation, ingestion, percutaneous absorption.

Health hazards: Irritation, hemolytic anemia and liver and kidney damage caused by high concentration.

Acute poisoning: Inhalation of high concentration of naphthalene vapor or dust causes eye and respiratory irritation, corneal clouding, headache, nausea, vomiting, loss of appetite, back pain,

frequent urination, protein and red and white blood cells in urine. Optic neuritis and retinitis may also occur. In severe cases, toxic encephalopathy and liver damage may occur.

Oral poisoning mainly causes hemolysis and liver and kidney damage, and even acute renal failure and liver necrosis.

Chronic poisoning: repeated exposure to naphthalene vapor can cause headache, weakness, nausea, vomiting and hematological damage.

It can cause cataract, optic neuritis and retinopathy. Skin contact can cause dermatitis.

Toxicological information and environmental behavior

Toxicity: It is a low toxicity category.

Carcinogenicity

Migration in the environment Several experiments have demonstrated the biodegradability of polycyclic aromatic hydrocarbons (PAHs).

Low molecular weight polycyclic aromatic hydrocarbons (PAHs) such as naphthalene, acenaphthene, and acenaphthylene were rapidly degraded in experimental studies.

More than 90% of PAHs were biodegraded within 7 days for liquids with initial concentrations of 5-10 mg/L.

High molecular weight PAHs such as fluoranthene, benzo(a)anthracene, quebracho, benzo(a)pyrene and and anthracene were difficult to be biodegraded.

5. Dangerous characteristics

Flammable when exposed to open flame and high heat. Emits toxic and irritating fumes when burning.

In contact with strong oxidizing agents such as chromic anhydride, chlorate and potassium permanganate, it can react strongly and cause combustion or explosion.

Powder and air can form an explosive mixture, when a certain concentration, when met with a spark will explode.

Combustion (decomposition) products: carbon monoxide, carbon dioxide.

Isolate the spill contaminated area and restrict access. Cut off the source of the fire.

Recommend emergency response personnel wear self-contained breathing apparatus and general operating overalls.

Do not come into direct contact with the spill. Small spills: Avoid dust and use non-sparking tools to collect in dry, clean, covered containers. Transport to an open area for detonation.

Or, if safe, burn in place. Large spills: Cover with plastic sheeting, canvas to reduce dispersion.

Use non-sparking tools to collect for recycling or transport to waste disposal sites for disposal.

6. First aid measures

Skin contact: Remove contaminated clothing and rinse skin thoroughly with soapy water and water.

Eye contact: Lift eyelids and flush with running water or saline. Seek medical attention.

Inhalation: Quickly remove from the scene to fresh air. Keep airway open. If breathing is difficult, give oxygen infusion. If breathing stops, give immediate artificial respiration.

Seek medical attention.

Ingestion: Drink sufficient warm water, induce vomiting, seek medical attention.

Extinguishing methods: extinguishing agents: fog water, carbon dioxide, sandy soil. Do not shoot the water stream directly to the molten material,

so as not to cause serious flow fire or cause violent boiling splash.

Package: Woven bag (lined with plastic bag) 50kg/bag, liquid refined naphthalene can be shipped by car tanker.

By Coco Ho

By Coco Ho