Introduction to Anionic Polymerization?

1.Introduction to Anionic Polymerization

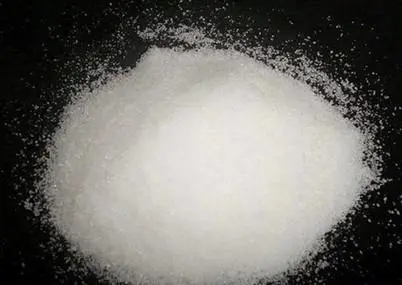

Anionic polyacrylamide (APAM) is a water-soluble polymer, mainly used for flocculation and sedimentation of various industrial wastewater, sedimentation and clarification treatment,

such as steel plant wastewater, electroplating plant wastewater, metallurgical wastewater, coal washing wastewater and other sewage treatment, sludge dewatering, etc..

It can also be used for drinking water clarification and purification treatment.

Since its molecular chain contains a certain number of polar groups, it can form large flocs by adsorbing the solid particles suspended in water,

bridging the particles or making the particles coalesce through charge neutralization, so it can accelerate the settling of particles in suspension,

and has a very obvious effect of speeding up the solution clarification and promoting filtration.

2. Functional characteristics of anionic polymers

Anionic polyacrylamide, as it has.

1. clarifying and purifying effect.

2、 Settling promotion effect.

3、 Filtration promotion effect.

4, thickening effect and other effects.

It can fully meet the requirements of various fields in waste liquid treatment, sludge thickening and dewatering, mineral processing, coal washing, paper making, etc.

Coal washing wastewater treatment program:

The treatment of coal sludge water in coal processing plant generally adopts the treatment process of “cyclone – thickener – filter press (coal sludge sedimentation tank)”.

Generally speaking, polymer flocculants (polyacrylamide) are purchased. The polymer flocculant is in contact with the coal sludge particles or coal sludge colloid,

which neutralizes the electrical properties of the coal sludge surface, reduces the surface energy, and causes the coal sludge particles to coalesce and precipitate.

The molecular weight of polyacrylamide is generally between one million, and different molecular weight flocculants should be used for coal slurry water with different particle size composition.

Polyacrylamide can be divided into three types: anionic polyacrylamide, cationic polyacrylamide and non-ionic polyacrylamide.

When using polyacrylamide for water treatment, make sure the type matches the pH value of coal sludge water,

anionic polyacrylamide is suitable for alkaline coal sludge water, cationic polyacrylamide is suitable for acidic coal sludge water, anionic and cationic polyacrylamide mixed use,

coal sludge water flocculation and sedimentation effect is better.

Features:

1、 Good water solubility, can be completely dissolved in cold water.

2、 Add a small amount of this anionic polyacrylamide product, you can receive great flocculation effect.

Generally only 0.01~10ppm (0.01~10g/m3) need to be added to give full play to the effect.

3、 Use the anionic polyacrylamide product and inorganic flocculant (polymerized ferric sulfate, polymerized aluminum chloride, iron salt, etc.)

at the same time, it can show greater effect.

Scope of application

1. Used in textile, printing and dyeing industry.

Polyacrylamide is used as sizing agent and finishing agent for fabric treatment, as well as a protective layer that can generate softness, anti-wrinkle and anti-mildew.

It can reduce the breaking rate when spinning fine yarn by using its strong moisture absorption.

Polyacrylamide as a post-treatment agent can prevent static electricity and flame retardation of fabrics.

When used as printing and dyeing auxiliaries, polyacrylamide can make the products attach fastness and brightness, and it can also be used as non-silicone polymer stabilizer for bleaching.

for suspended particles, coarse, high concentration, particles with cationic charge, water PH value is neutral or alkaline sewage, because the anionic polyacrylamide molecular chain contains a certain amount of polar groups can adsorb the suspended solid particles in water

, so that the bridge between the particles to form a large flocculent.

Therefore, it accelerates the settling of particles in suspension, has a very obvious effect of speeding up the clarification of the solution and promoting filtration, etc.

This product is widely used in the treatment of chemical industrial wastewater and waste liquid, municipal sewage treatment.

Water treatment for tap water industry, purification of high turbidity water, sinking and clearing, coal washing, mineral processing, metallurgy,

steel industry, zinc, aluminum processing industry, electronic industry, etc.

3、Used in petroleum industry, oil recovery, drilling mud, waste mud treatment, prevent water run-off, reduce friction, improve recovery rate, three times oil recovery is widely used.

4, used in the paper industry, one is to improve the filler, pigments and other retention rate.

To reduce the loss of raw materials and pollution of the environment; the second is to improve the strength of paper (including dry strength and wet strength),

in addition, the use of PAM can also improve the paper tear resistance and porosity to improve visual and printing performance, but also used in food and tea packaging paper.

5, other industries, food industry, for cane sugar, beet sugar production in cane juice clarification and syrup phosphorus floatation extraction.

Enzyme preparation fermentation liquid flocculation clarification industry , also used in feed protein recovery, stable quality, good performance, the recovery of protein powder to improve the survival rate of chickens and weight gain,

egg production without adverse effects, synthetic resin coatings, civil construction grouting materials plugging,

building materials industry, improve the quality of cement, construction industry adhesives, caulking repair and plugging agent, soil improvement, electroplating industry, printing and dyeing industry, etc.

3. Packaging and storage of anionic polymers

It is packed in 25Kg plastic-lined woven bags or paper-plastic composite bags, or according to user’s requirements.

When storing and transporting, pay attention to prevent heat and moisture, prevent the package from breaking,

dry powder products will absorb moisture and caking if left open for a long time. The number of stacking layers should not exceed 20 layers.

The effective storage period is 2 years. The particle size of the product is 20-80 mesh.

By Coco Ho

By Coco Ho