Anhydrous ethanol (Ethanol absolute), is an aqueous solution of ethanol with high purity.

In general, the concentration of 99.5% ethanol solution is generally called anhydrous ethanol, anhydrous ethanol is a mixture of ethanol and water.

1.Anhydrous ethanol composition

A mixture of ethanol and water, generally a 99.5% ethanol solution.

2. Chemical properties of anhydrous ethanol

Elimination reaction: ethanol is rapidly heated to 170°C under concentrated sulfuric acid to produce ethylene, and concentrated sulfuric acid is used as dehydrating agent and catalyst.

Substitution reaction: ethanol reacts with hydrobromic acid under heating conditions to produce bromoethane and water.

Intermolecular dehydration: ethanol is heated to 140°C under concentrated sulfuric acid to produce ethyl ether and water.

Esterification reaction: ethanol and carboxylic acid are heated in the presence of concentrated sulfuric acid to produce the corresponding ester compounds.

Reaction with sodium metal: ethanol reacts with sodium metal to produce sodium ethanol and hydrogen gas.

Reaction with strong oxidizing agents: ethanol reacts with acidic potassium permanganate solution or acidic potassium dichromate solution and can be oxidized to acetic acid.

3.Anhydrous ethanol function and use

Ethanol is an important organic solvent, widely used in various aspects of medicine, paint, hygiene products, cosmetics, grease, etc.

,accounting for about 50% of the total consumption of ethanol.

Ethanol is an important basic chemical raw material, used in the manufacture of acetaldehyde, ethylene, ethylamine, ethyl acetate, acetic acid, chloroethane and so on,

and derived from many intermediates of pharmaceuticals, dyes, paints, spices, synthetic rubber, detergents, pesticides and other products, its products up to more than 300 kinds,

ethanol as intermediates of chemical products is gradually declining, many products such as acetaldehyde, acetic acid no longer use ethanol as raw materials, and use other raw materials instead.

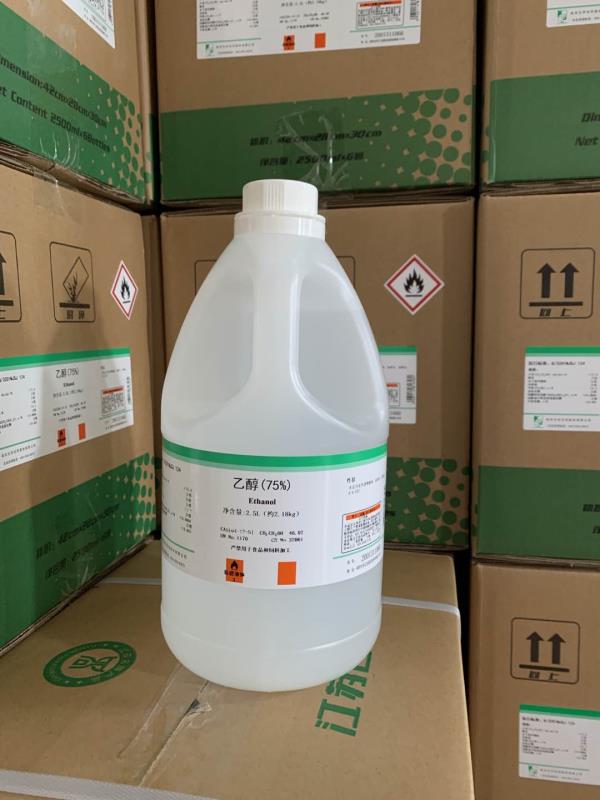

The 75% aqueous solution of ethanol has strong bactericidal ability and is a common disinfectant.

Specially refined ethanol can also be used to make beverages. Similar to methanol, ethanol can be used as an energy source.

Some countries have started using ethanol alone as a motor fuel or blended into gasoline (10% or more) to save gasoline.

4. Precautions for the use of anhydrous ethanol

(1) Overview of hazards

Health hazard: This product is a central nervous system depressant.

It first causes excitation, followed by inhibition. Acute poisoning: Acute poisoning occurs mostly by oral administration.

It can be generally divided into four stages: excitation, hypnosis, anesthesia and asphyxia. Patients enter the third or fourth stage with loss of consciousness, dilated pupils,

irregular breathing, shock, cardiac circulatory failure and respiratory arrest. Chronic effects:

Long-term exposure to high concentrations of the product in production can cause symptoms of nasal, eye, and mucous membrane irritation, as well as headache, dizziness, fatigue, agitation, tremor, and nausea.

Long-term alcohol abuse can cause polyneuropathy, chronic gastritis, fatty liver, liver cirrhosis, myocardial damage and organic psychosis, etc.

Long-term skin contact can cause dryness, flaking, cracking and dermatitis.

Flammability hazard: The product is flammable and irritating.

(2) First aid measures

Skin contact: Remove contaminated clothing and rinse with running water.

Eye contact: Lift eyelids and flush with running water or saline. Seek medical attention.

Inhalation: Quickly remove from the scene to fresh air. Seek medical attention.

Ingestion: Drink sufficient warm water and induce vomiting. Seek medical attention.

(3) Fire-fighting measures

Hazardous characteristics: flammable, its vapor and air can form an explosive mixture, in contact with open flame, high heat can cause combustion and explosion.

Contact with oxidizing agents to chemical reaction or cause combustion. In the fire, the heated container has the risk of explosion.

Its vapor is heavier than air, can be spread to a considerable distance at a lower level, and will catch fire when encountering an ignition source back to combustion.

Fire extinguishing methods: move the container from the fire to the open area as far as possible.

Spray water to keep the fire container cool, until the end of the fire.

Extinguishing agents: anti-soluble foam, dry powder, carbon dioxide, sand and soil.

(4) Spill emergency treatment

Emergency treatment: quickly evacuate people in the contaminated area of the spill to a safe area and isolate, strictly limit access.

Cut off the source of fire. It is recommended that emergency personnel wear self-contained positive pressure respirators and anti-static overalls.

Cut off the source of the spill if possible. Prevent flow into restricted spaces such as sewers and flood drains.

Small spills: adsorb or absorb with sand or other non-combustible materials.

Can also be flushed with large amounts of water, washed and diluted into the wastewater system.

Large spills: Construct a dike or dig a pit to take in.

Cover with foam to reduce vapor hazard. Transfer to tanker or special collector with explosion-proof pump, recycle or transport to waste disposal site for disposal

5. Anhydrous ethanol preparation method

Synthesis methods

Prior to the 1930s, the fermentation method was an industrial production method for ethanol.

With the rapid development of petrochemicals, the production of synthetic method ethanol is increasing. However, the isomeric high-carbon alcohols entrapped in synthetic method ethanol are unsuitable for use as beverages,

food, medicine and spices because of their paralyzing effects on the higher nerve centers of humans.

Therefore, even in countries with developed petrochemical industry, fermentation method ethanol still occupies a certain proportion.

[Fermentation method

The starch-rich agricultural products such as cereals, potatoes, or wild plant fruits are washed and crushed, then pressure-cooked to make starch paste, then add the right amount of water,

cool to about 60 ℃ and add amylase, so that starch is hydrolyzed into maltose and glucose in turn. Then add the enzyme mother bacteria for fermentation to produce ethanol.

[Hydrolysis method

Produced by addition reaction with ethylene and water as raw materials. There are two types of hydrolysis:

indirect hydrolysis and direct hydrolysis. Indirect water law is also called sulfate method, the reaction is carried out in two steps.

First, 95-98% sulfuric acid and 50-60% ethylene at 2:1 (weight ratio) in the tower reactor absorption reaction, 60-80 ℃, 0.78 ~ 1.96 MPa conditions to generate sulfate ester.

The second step is to hydrolyze the sulfate ester in a hydrolysis tower at 80-100°C and 0.2-0.29 MPa pressure to yield ethanol,

while generating the by-product ether. The alkene reacts directly with water to produce ethanol. Direct hydrolysis is a one-step process.

It is made by hydration of ethylene and water under high temperature and pressure in the presence of phosphoric acid catalyst.

This method is simple, less corrosive, does not require special steel, the amount of by-product ether is small, but requires high purity of ethylene,

high power consumption. Whether by fermentation or ethylene hydration, the ethanol produced is usually an azeotrope of ethanol and water, i.e.

industrial ethanol with a concentration of 95%.

By Coco Ho

By Coco Ho