Buying Guide: Polymer

If polymer is one of the essential ingredients for your industrial processes, then this guide is worth your attention.

Let’s explore the fundamentals and applications of polymers.

What is a Polymer?

A polymer is a synthetic or natural substance composed of large molecules formed by repeating structural units (monomers), typically connected by covalent bonds. Polymers exist in various ionic forms—anionic, cationic, and nonionic—and are widely used as flocculants, thickeners, binders, emulsifiers, and film-forming agents across numerous industries.

They exhibit excellent water solubility (for hydrophilic types), flexibility in formulation, and strong bonding or bridging capabilities—making them ideal for use in processes like filtration, sedimentation, stabilization, and rheology modification.

How to Identify a Polymer

Most polymers used in industrial applications appear as white granular, powder, or emulsion forms. Identification is generally based on:

-

Molecular structure (linear, branched, or crosslinked)

-

Ionic charge (cationic, anionic, nonionic)

-

Solubility and viscosity behavior

-

Formulation purpose (thickening, flocculating, binding, etc.)

For custom applications, polymers may be blended with other agents to improve performance—especially in areas like water treatment and waste management.

Chemical Properties of Polymers

-

Synthetic or natural macromolecules

-

High molecular weight with variable chain configurations

-

Available in powder, granular, bead, or emulsion form

-

Reactivity often influenced by pH, temperature, and ionic strength

-

Ionic types: anionic, cationic, nonionic

-

Can be hydrophilic, hydrophobic, or amphiphilic

Polymer Applications

Polymers are multifunctional materials with wide industrial applications:

Water Treatment

Used to clarify water, dewater sludge, and aggregate suspended particles in municipal and industrial water systems.

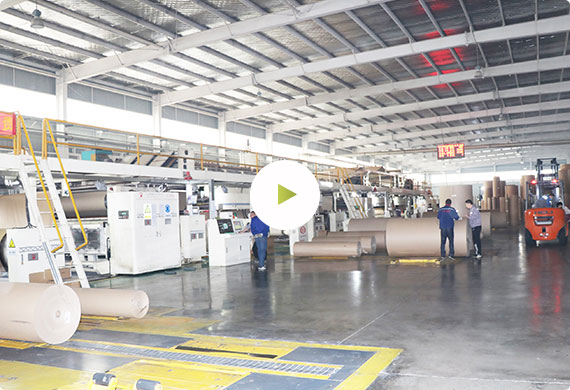

Paper Industry

Improves fiber retention, drainage efficiency, and sheet formation during paper production.

Oil Recovery

Employed in enhanced oil recovery (EOR) operations to increase oil extraction efficiency through viscosity control and particle dispersion.

Textile and Dyeing

Acts as a sizing agent, dye fixative, and viscosity modifier, ensuring smoother, more uniform dyeing and finishing.

Mining and Metallurgy

Assists in ore flotation, tailings thickening, and coal washing by improving solid-liquid separation.

Agriculture

Improves soil structure, moisture retention, and erosion resistance, and is also used in controlled-release formulations.

Polymer Grades & Solutions

Polymers are engineered in different molecular weights and charge densities:

-

High molecular weight: Ideal for sludge dewatering and solid-liquid separation.

-

Medium molecular weight: Common in paper processing and emulsification.

-

Low molecular weight: Suitable for cosmetic, pharmaceutical, and homecare formulations.

Typical usage concentrations range from 0.05% to 0.5%, depending on the specific application and desired performance.

Is a Polymer a Reducing Agent?

Most polymers are not reducing agents, but they are often used in combination with chemical compounds that participate in redox, precipitation, or transformation reactions, especially in environmental remediation or industrial water systems.

Is a Polymer Toxic?

The toxicity of a polymer largely depends on its monomer content and additives. While many industrial polymers are safe when fully polymerized, raw or residual monomers (e.g., acrylamide, formaldehyde) can be toxic. Always refer to:

-

Material Safety Data Sheets (MSDS)

-

Handling protocols

-

Regulatory compliance (REACH, NSF, etc.)

Is a Polymer Explosive?

No, most polymers are not explosive under standard conditions. However, certain monomers or polymerization agents may be hazardous. Polymers should not be mixed with strong oxidizers or subjected to uncontrolled heating.

Polymer vs. Other Materials

Polymers stand out for their:

-

High flocculation efficiency

-

Excellent binding or bridging ability

-

Wide functional range across industries

Compared to alternatives like sodium carboxymethyl cellulose, polyethylene glycol, or natural gums, polymers offer:

Purity of Polymers

Industrial polymers should meet stringent purity standards:

-

>90% purity is common for performance applications

-

<0.05% residual monomer content for safe use in sensitive sectors (e.g., food, drinking water)

Certifications like ISO, REACH, or NSF are often required depending on the industry.

Polymer Price & Supplier Considerations

Polymer pricing depends on several factors:

Choose suppliers that offer:

-

Consistent product quality

-

Full technical documentation (MSDS, COA)

-

Tailored formulation options

-

Appropriate packaging for bulk storage

Avoid suspiciously cheap polymers that may contain high monomer residue or unstable formulations.

How to Buy a Polymer

To buy the right polymer:

-

Define requirements – Choose ionic type, molecular weight, and form (powder/emulsion).

-

Request datasheets – Review specs, purity, and test results.

-

Test with samples – Evaluate compatibility with your process.

-

Check packaging – Ensure proper sealing for moisture protection.

-

Inspect shipments – Confirm labeling, batch number, and COA details.