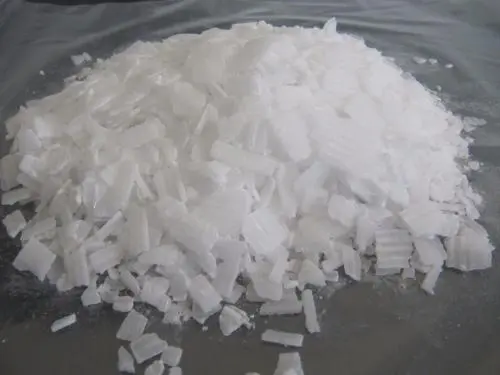

Caustic soda generally refers to sodium hydroxide, sodium hydroxide, inorganic compound, chemical formula NaOH, also known as caustic soda, caustic soda, solid soda, caustic soda, caustic soda.

Sodium hydroxide is strongly alkaline and highly corrosive, and can be used as acid neutralizer, matching masking agent, precipitation agent, precipitation masking agent, color developer, saponification agent, peeling agent, detergent, etc.

It has a wide range of uses.

There are two methods of industrial production of sodium hydroxide: causticization and electrolysis.

Causticizing method is divided into soda ash causticizing method and natural alkali causticizing method according to different raw materials;

electrolytic method can be divided into diaphragm electrolytic method and ion exchange membrane method.

Staff should be well protected, if they accidentally touch the skin and eyes, they should immediately flush clean with plenty of water.

The working environment should have good ventilation.

The aqueous sodium hydroxide solution has a slippery feeling and generates high heat when dissolved in water,

so it should be operated with protective goggles and rubber gloves, and be careful not to splash on the skin or in the eyes.

1. Caustic soda properties and toxicological information

Sodium hydroxide is strongly alkaline and has strong hygroscopicity.

Easily soluble in water, exothermic when dissolved, aqueous solution is alkaline, with slippery feeling;

extremely corrosive, corrosive to fiber, skin, glass, ceramics, etc. React with metal aluminum and zinc, non-metal boron and silicon, etc.

to release hydrogen; disproportionation reaction with chlorine, bromine, iodine and other halogens; neutralization with acids to produce salt and water.

Toxicological information

Sodium hydroxide is moderately toxic.

Its hazardous properties are: in contact with water and water vapor, it exerts a lot of heat and forms corrosive solutions.

Neutralization reaction with acid and exothermic. It is highly corrosive. Combustion (decomposition) products: may produce harmful toxic fumes.

The invasion route is: inhalation, ingestion. The health hazard is: strongly irritating and corrosive.

The dust or fumes irritate the eyes and respiratory tract and corrode the nasal septum; direct contact with skin and eyes can cause burns;

accidental ingestion can cause burns in the digestive tract, mucous membrane erosion, bleeding and shock.

2. Caustic soda purification

The impurities contained in sodium hydroxide are usually iron, sodium chloride, silicate, carbonate, etc.

Take 100g of industrial sodium hydroxide dissolved in 1L of anhydrous ethanol (without acetaldehyde), filtered in dry air without carbon dioxide and moisture to remove impurities such as chloride, carbonate, silicate, etc.

Concentrate the filtrate to remove ethanol, and with the concentration separate off the generated solid sodium ethanol.

Wash several times with pure anhydrous ethanol, and remove the residual ethanol by heating under reduced pressure for a long time, then sodium hydroxide with a purity of about 99.8% is obtained.

Sodium hydroxide is mainly used in the production of paper, cellulose pulp and soap, synthetic detergent, synthetic fatty acid production and the refining of animal and vegetable oils and fats.

Textile printing and dyeing industry used as cotton desizing agent, cooking agent and mercerizing agent.

The chemical industry is used to produce borax, sodium cyanide, formic acid, oxalic acid, phenol, etc.

The petroleum industry is used to refine petroleum products and used in oilfield drilling mud.

It is also used in the production of alumina, surface treatment of zinc metal and copper metal, as well as in glass, enamel, tanning, medicine, dyes and pesticides.

Food grade products are used in the food industry as acid neutralizer, as peeling agent for citrus and peaches,

and as detergent for empty bottles, empty cans and other containers, as well as decolorizer and deodorizer.

When sodium hydroxide is used as basic reagent, it can be used as neutralizing agent, matching masking agent,

precipitating agent, precipitation masking agent, absorbent for small amount of carbon dioxide and water, color developer for determination of ketosteroids by thin layer analysis, etc.

It is widely used in manufacturing various sodium salts, soap, pulp, finishing cotton fabric, silk, viscose fiber, regeneration of rubber products, metal cleaning, electroplating, bleaching, etc.

In cosmetic creams, sodium hydroxide and stearic acid and other saponification act as emulsifiers, used to make snow cream, shampoo,

3. Caustic soda storage

Sodium hydroxide should be stored in a cool, dry and well-ventilated storehouse.

It should be far away from fire and heat source. The temperature of the warehouse should not exceed 35℃ and the relative humidity should not exceed 80%.

The package must be sealed, do not get wet. Should be stored separately from flammable (combustible) materials, acids, etc.,

do not mix storage. The storage area should be equipped with suitable materials to shelter leaks.

4. Caustic soda emergency measures

Eye contact: Immediately lift eyelids, flush with running water or saline for at least 15 minutes, or flush with 3% boric acid solution, and seek medical attention quickly.

Inhalation: Get out of the scene quickly and use fresh air. Perform artificial respiration if necessary and seek medical attention quickly.

Ingestion: rinse mouth immediately when patient is awake, take diluted vinegar or lemon juice orally, seek medical attention quickly.

Leak treatment

Isolate the spill contaminated area, set up warning signs around it, and advise emergency responders to wear gas masks and chemical protective clothing.

Do not touch the spill directly, flush with large amounts of water, and put diluted wash water into the wastewater system.

If large amounts are spilled, collect and recycle or dispose of after harmless treatment.

Fire-fighting methods

Fire-fighting methods: Firefighters must wear overalls (made of anticorrosive materials).

5. Caustic soda sodium hydroxide aqueous contamination treatment

For sodium hydroxide leakage into the water, according to the estimated amount of leakage and the characteristics of the water body for the corresponding treatment.

According to the water body environment and monitoring pH condition to decide whether to throw or throw how much acid neutralization, add how much water dilution.

Analysis method.

The determination of sodium hydroxide concentration is usually done by acid-base neutralization titration method, using methyl orange as indicator and titrating with standard solution of hydrochloric acid until the end point from yellow to orange.

Water pollution sulfuric acid neutralization

Concentrated sulfuric acid is first diluted and then added, and the minimum amount of sulfuric acid required to neutralize sodium hydroxide can be calculated by the formula y=125.07x;

y is the added mass of concentrated sulfuric acid with a concentration of 98%;

x is the leaked mass of sodium hydroxide, i.e. x=ωm, ω is the mass fraction of leaked sodium hydroxide, and m is the mass of leaked sodium hydroxide.

By Coco Ho

By Coco Ho